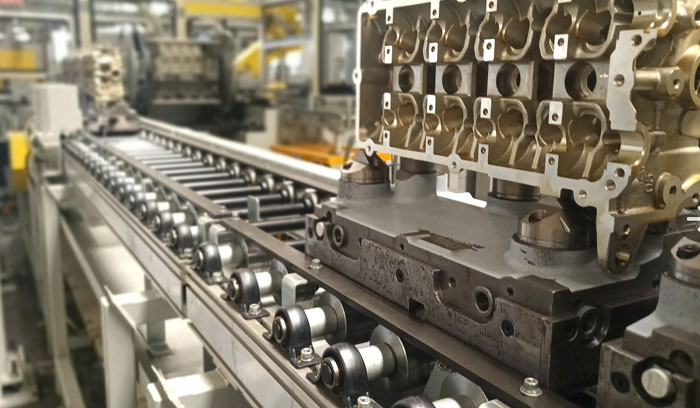

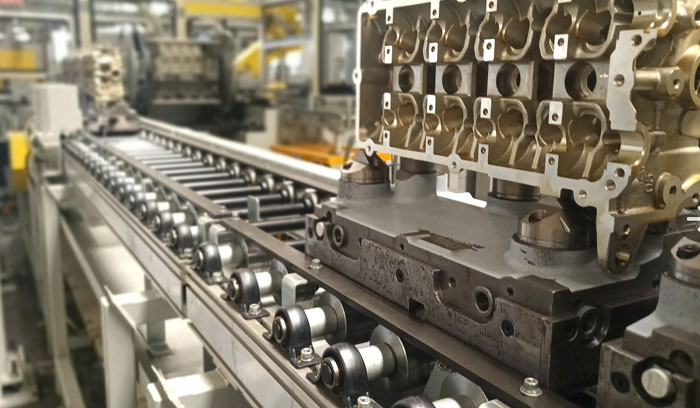

Friction roller line commutator is one of the commonly used equipment in industrial production, it can transfer wire from one roller to another roller, and play the role of wire commutation. However, due to the different types of wire, thickness, and different needs of the production line, we need to overload the friction roller line commutator to meet different needs.

First, we can overload from the material side. At present, the common friction roller line commutation equipment has two kinds of metal and plastic. The metal friction roller has high strength and wear resistance, and is suitable for thick wire or production scenarios with high strength requirements, such as steel, automotive and other industries. The plastic friction roller is lighter and has better corrosion resistance, which is suitable for thin wire or production scenarios with low weight requirements, such as electronics, textile and other industries. Therefore, when the heavy friction roller line commutator, we can choose the material according to the needs of the specific production line to achieve the best use effect.

Second, we can overload in terms of structure. At present, the common friction roller line commutator has different structures such as linear, arc and multistage. The linear friction roller line commutator is suitable for the linear production line or the scene with long wire, which can improve the production efficiency; Arc type friction roller line commutator is suitable for arc line production line or the scene requiring high commutation Angle of wire rod, which can improve the accuracy of commutation. The multistage friction roller line commutator is suitable for the scene of multiple wire commutation at the same time, which can improve the production efficiency. Therefore, when heavy-duty friction roller line commutator, we can choose the appropriate structure according to the shape, length and commutation Angle of the specific production line wire to improve production efficiency and quality.

In addition, we can also overload from the driver mode. At present, there are two common driving modes of friction roller line commutator: electric drive and pneumatic drive. The electric drive friction roller line commutator is suitable for scenarios that require high commutation speed and force, and can provide a large torque and speed range, such as heavy industrial production lines; The pneumatic actuated friction roller line commutator is suitable for scenarios where the commutation force is low and can provide high commutation speed and accuracy, such as light production lines. Therefore, when the heavy friction roller line commutator, we can choose the appropriate drive mode according to the needs and requirements of the specific production line to improve production efficiency and quality.

In summary, the heavy-duty friction roller line commutator can be carried out from many aspects such as material, structure and driving mode. We can choose the appropriate heavy loading method according to the needs and requirements of the specific production line to improve production efficiency and quality. Different heavy loading methods can meet different production needs, thus providing more choices and possibilities for the development of industrial production lines.

No. 3, Guangda Road, Zhitang Industrial Park, Changshu City