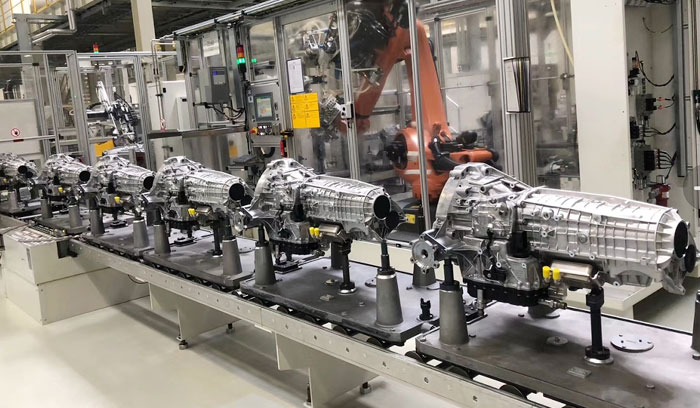

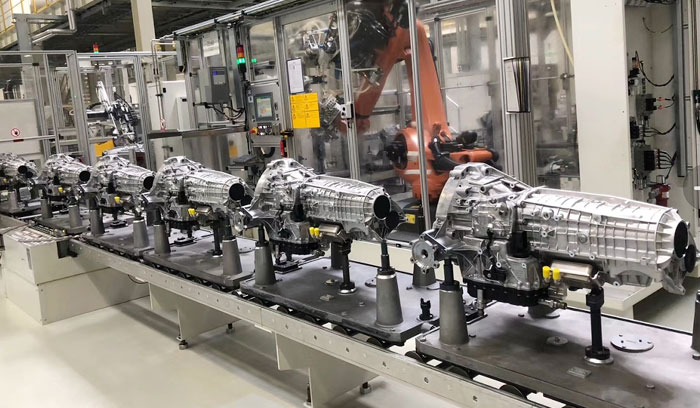

The mechanical structure of friction roller is a common transmission mechanism, which realizes the transfer of force and the conversion of motion through friction. In engineering, the mechanical structure of friction roller is widely used in various mechanical equipment and systems, and has the advantages of simple structure, high efficiency and smooth movement. In some cases, in order to meet the specific engineering requirements, it is necessary to design the mechanical structure of the friction roller line with heavy loads. Heavy load friction roller mechanical structure mainly includes structural design, material selection and strength check, these aspects will be elaborated in detail below.

First of all, the structural design of the heavy-duty friction roller line mechanical structure needs to be designed according to the specific application requirements and working conditions. In general, the heavy-duty friction roller line mechanical structure needs to be durable, stable and reliable. Load characteristics, working environment and other relevant factors need to be considered in the design. For example, if high-speed transmission is required, the transmission effect can be improved by increasing the diameter of the rollers or reducing the distance between the rollers. In addition, in order to ensure the stability and reliability of the structure, the structure should be rationally arranged and the number of connecting parts should be increased. In addition, in order to run smoothly, the roller seal device can also be installed to effectively avoid the problem of roller sliding instability caused by interference from external factors.

Secondly, for the selection of materials for the heavy-duty friction roller line mechanical structure, it is necessary to determine the appropriate materials according to the requirements of structural design. In general, the heavy-duty friction roller line mechanical structure needs to have high strength and wear resistance. Commonly used materials are cast iron, steel and so on. In the selection of materials need to consider the strength of the material, hardness, wear resistance, corrosion resistance and other factors. In addition, the processing performance and reliability of the material should be considered to ensure the normal use of the structure.

Finally, it is necessary to calculate and analyze the strength check of the mechanical structure of heavy load friction roller line according to the designed load and force. Generally speaking, strength checking includes statics and dynamics. Static analysis is mainly to calculate and check the strength and stiffness of the structure, including force analysis, stress analysis, deformation analysis and so on. Dynamic analysis is mainly to calculate and check the vibration, shock and dynamic load of the structure. Strength check can determine the safety and reliability of the structure, so as to ensure the normal use of the structure under heavy load conditions.

In summary, the design of mechanical structure of heavy-duty friction roller line needs to consider structural design, material selection and strength check. Through reasonable structure design, material selection and strength check, the mechanical structure of heavy-duty friction roller line can be guaranteed to have good performance and reliability in engineering applications.

No. 3, Guangda Road, Zhitang Industrial Park, Changshu City