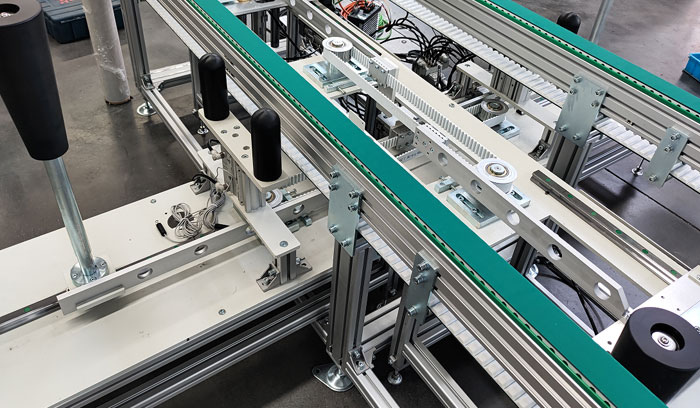

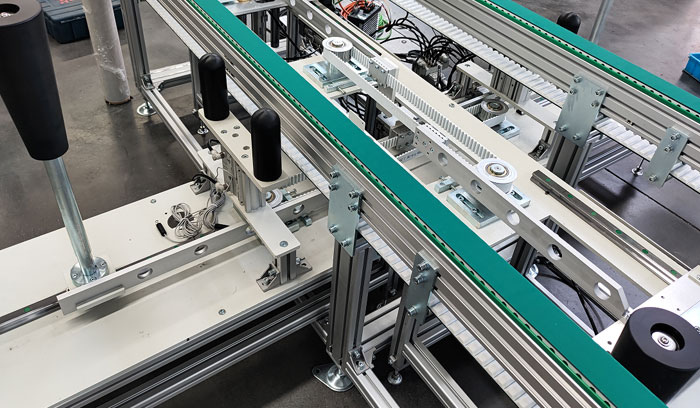

Synchronous belt conveyor lines are a common conveyor device that can be used in many different applications. However, there are many factors to consider when choosing the right synchronous belt conveyor line. This article will cover some of the factors that go into choosing a synchronous belt conveyor line and provide some practical tips to ensure the correct selection of equipment.

1. Working environment and special requirements required

The first thing to consider is the working environment in which the belt conveyor line will be used. For example, whether the conveyor line needs to be waterproof, dustproof, corrosion resistant, or needs to work in a high or low temperature environment. In addition, if a conveyor line is to be used in the food or pharmaceutical industry, it is also necessary to understand the special requirements required, such as the need to meet hygiene standards.

2. Load capacity and conveying speed

Another factor to consider is the load capacity of the synchronous belt conveyor line, including its maximum load weight and transmission speed. These factors need to be evaluated against the actual situation to ensure that the transmission line can meet the required load capacity and speed requirements.

3. Length and width of conveying line

It is necessary to consider the length and width of the conveyor line, which will directly affect the scope of application of the conveyor line. If the items to be transported are very long or wide, then you need to choose a larger size of the conveyor line to ensure that the goods can be effectively transported.

4. Shape of conveyor line

Synchronous belt conveyor line can be used in a variety of different shapes. For example, linear transmission line, S type transmission line, ring transmission line and so on. It is necessary to choose the right shape according to the characteristics of the goods and the working environment.

5. Width and length of the synchronization tape

The width and length of the synchronization belt also need to be considered, which will directly affect the load capacity and transmission speed of the transmission line. The wider the width of the synchronization belt, the greater its carrying capacity and speed.

6. Material and structure of the synchronization belt

The material and structure of the synchronization belt also need to be considered. For example, some synchrobelts are made of rubber, while others are made of polyurethane (PU). These materials vary in performance and price, and the appropriate synchronization belt needs to be selected according to the specific situation.

7. Reliability and maintenance convenience of the system

Finally, it is necessary to consider the reliability and maintenance convenience of the synchronous belt conveyor system. If the system is easy to service, then any problems can be resolved more quickly and keep the production line running.

In short, choosing the right synchronous belt conveyor line needs to consider many factors. It is necessary to understand the special requirements required, load capacity and conveying speed, length and width, shape, width and length of synchronization belt, material and structure and so on. In addition, the reliability and ease of maintenance of the system also need to be considered. By comprehensively evaluating these factors, the most suitable synchronous belt conveyor line equipment can be selected, thereby improving production efficiency and the normal operation of the production line.

No. 3, Guangda Road, Zhitang Industrial Park, Changshu City